Imagine painting an entire apartment building, or a stadium, or an office building. If it takes approximately eight litres of Resene paint to cover a 48sqm living room with two coats, you can imagine how much paint it takes to cover the inside of an entire apartment building – thousands of litres! But the painters tasked with painting such large spaces don’t bat an eyelid, and neither do Norm and the team at the Resene Big Batch facility.

“Here at Resene Big Batch we make batches of paint ranging from 2500 litres all the way up to 18,000 litres,” says Norm, Naenae Plant Operations Manager.

“The majority of our work is with white paint, which is a big priority for us and it’s the bread and butter of Resene manufacturing.”

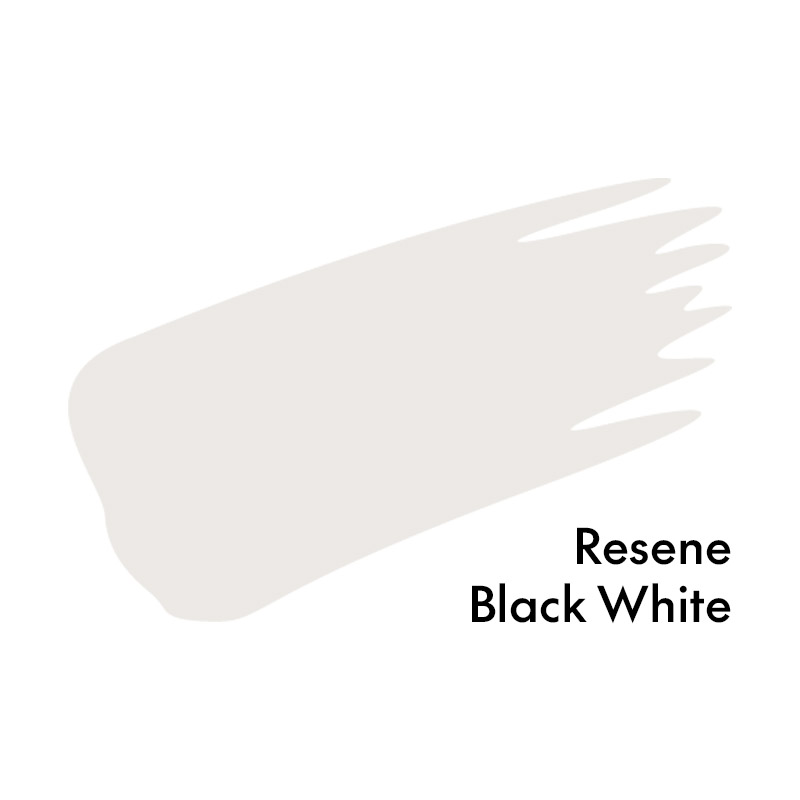

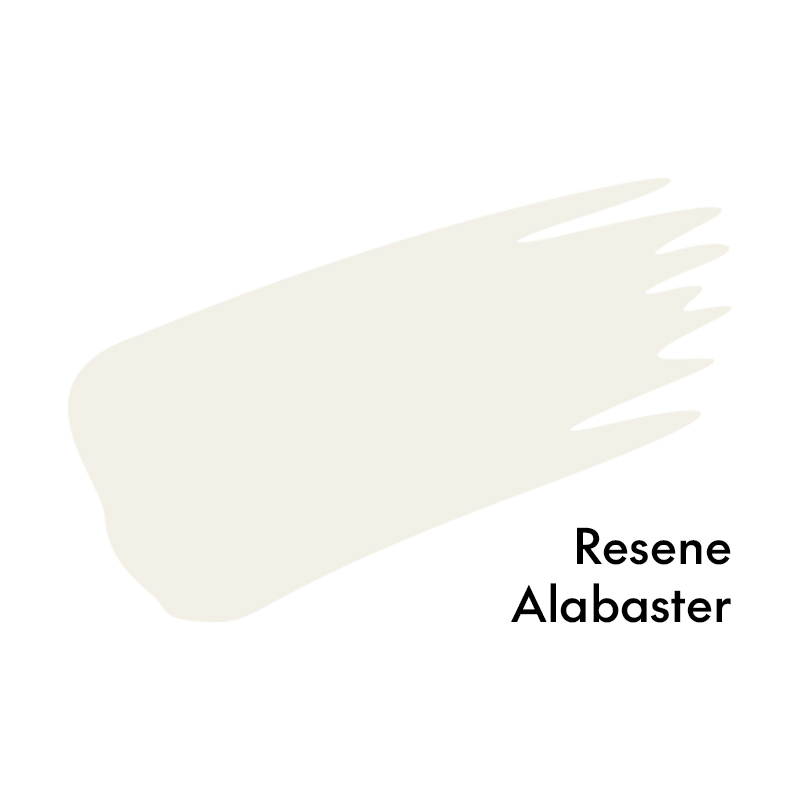

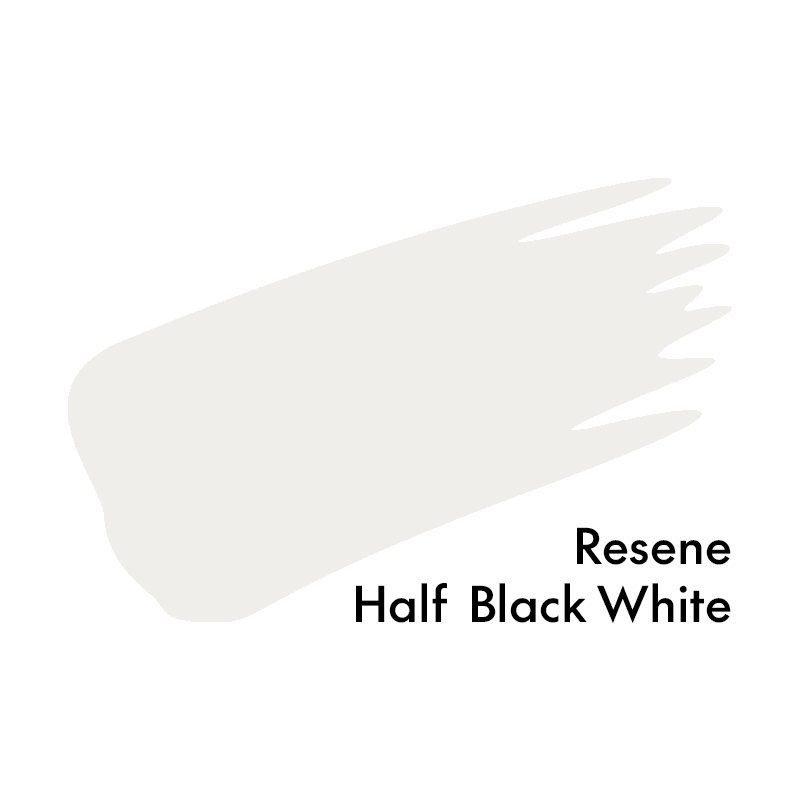

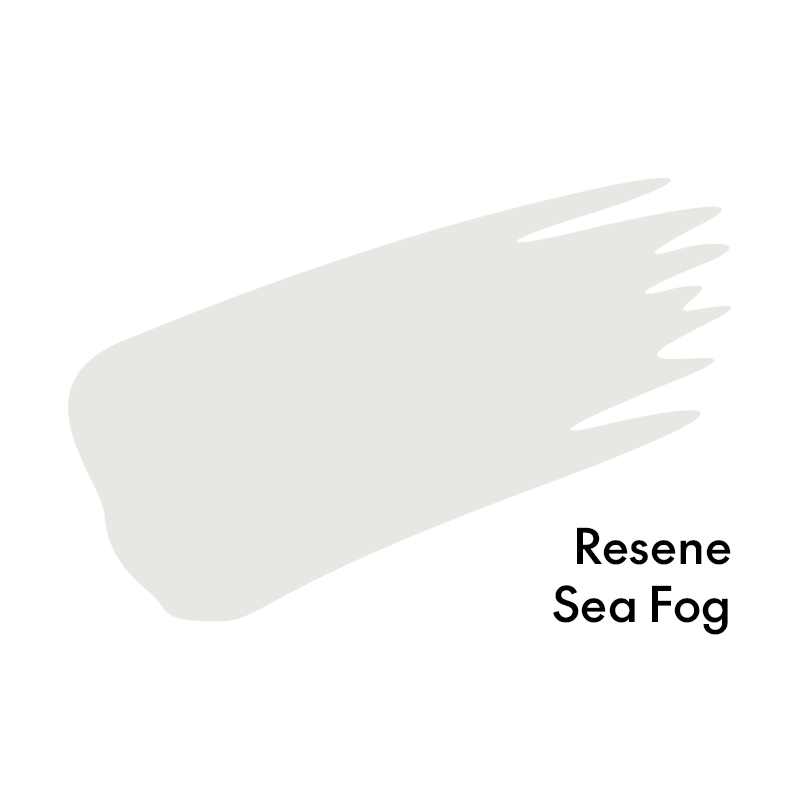

Did you know that Resene’s 20 most popular paint colours are all paints from the Resene Whites & Neutrals range? Resene Black White, a chalky white with a hint of black, was Resene’s highest-selling paint last year taking out the top spot for the sixth year in a row. Resene Black White was followed by Resene Alabaster, a crisp white with a black edge, Resene Half Black White and Resene Sea Fog, a misty white with a hint of grey.

While the hardest part for most is choosing which of the huge Resene paint colours to use in their home, paint manufacturing is a technical business for the Resene Big Batch team. The majority of Resene’s extensive paint range, including popular Resene SpaceCote for interiors and Resene Lumbersider for exteriors, are waterborne meaning they are water-based. Water is combined with precise amounts of binders and pigments to produce a base colour paint. Binders are what allows paint to stick to a surface and pigments are added to the binders to create physical properties such as gloss/sheen. Resene paints come in a wide range of bases from white through to ultra deep and specialist red, yellow and ultra tones, which are then tinted to produce the required colour.