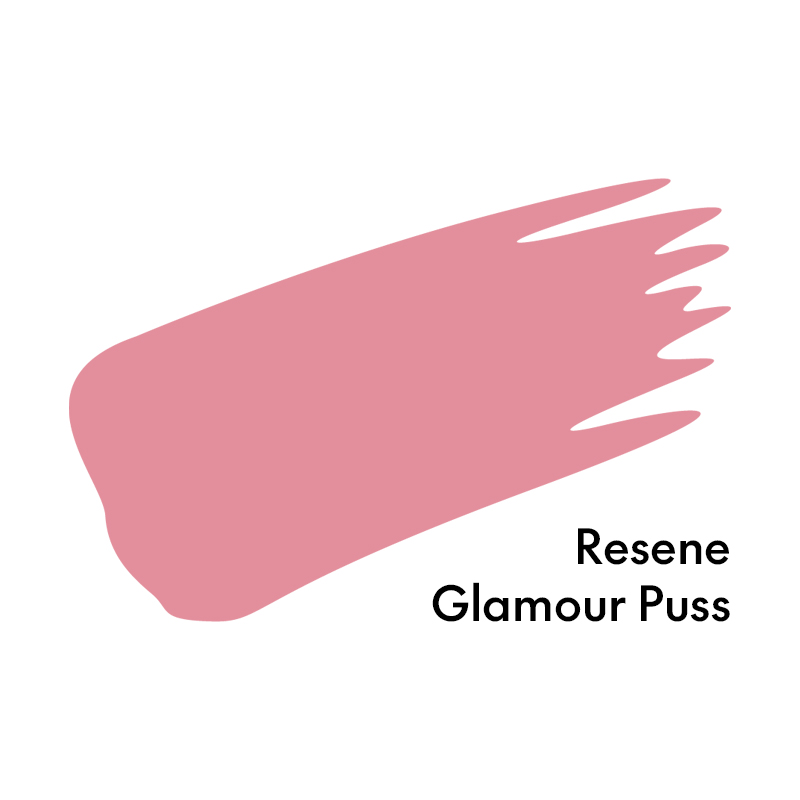

A visit to the Resene Group Tinting Facility in Lower Hutt comes with a bit of razzle dazzle. This busy area is where Resene paints are given their colour tints for large and specialised projects – and it’s full of personality. There’s colourful pictures on the walls, a pail of Resene Glamour Puss on the paint mixing machine and it’s the workplace of Resene’s resident style icon, Lui (whose amazing tie collection is not to be missed).

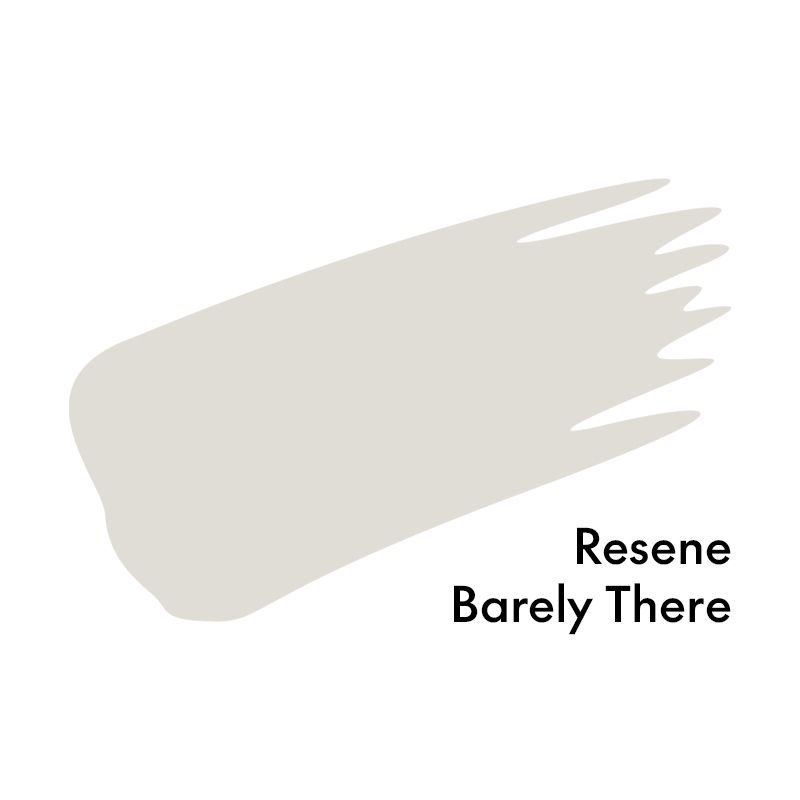

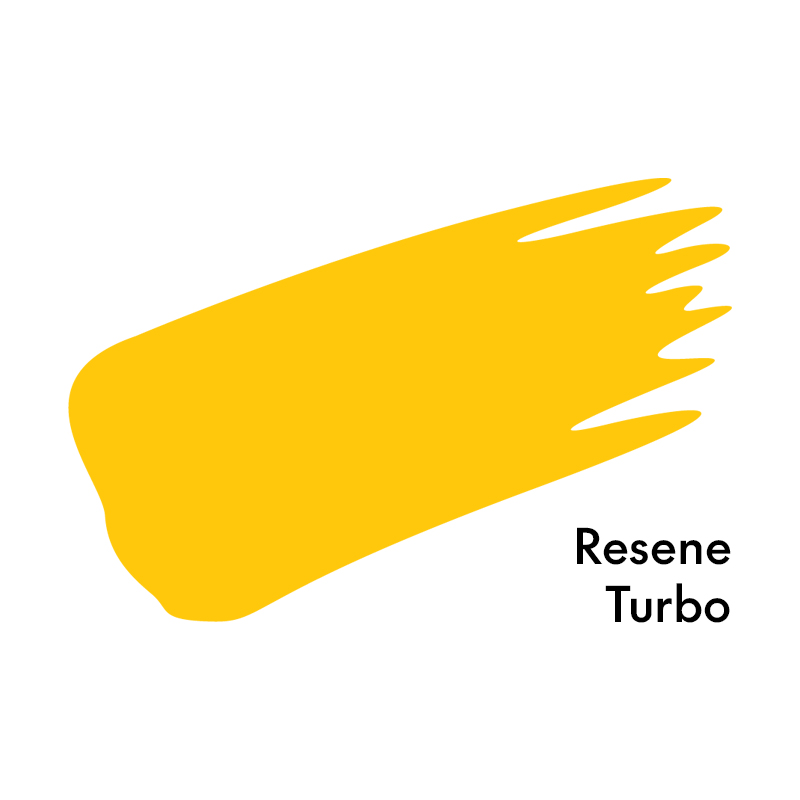

The Group Tinting Facility colours “everything and anything”, from pale and neutral tones such as Resene Barely There to full-throttle yellows such as Resene Turbo. This vibrant area of the Resene manufacturing facility often attracts staff from other areas of the business who stop by for their daily dose of fun and colour.

“We try to keep people happy. Some people come here to get away from it all and enjoy the plants and the colour,” says Lui. “It’s pretty cool here.”

Shake it up

To create Resene’s vibrant colours, Lui and the team put Resene paint tones onto a paint tinting carousel, adding precise formulas of pigments into each container before they are shaken in the industrial mixing machine for two minutes and thirty seconds. The colours are then painted onto a special swatch for quality control. “The Colour Lab will double check the colour and we can do adjustments if need be,” explains Lui.